Modular construction provides a true alternative to traditional construction methods, offering speed, sustainability, and design flexibility.

Yet despite its proven performance, many modular construction myths still circulate in the industry. As a leader in modular building, Triumph Modular hears them all the time—and we’re here to set the record straight.

In this post, we’ll debunk five of the most common myths about modular construction and explain why it’s a modern, adaptable, and high-quality solution for commercial, educational, and institutional needs.

Myth #1: Modular Means No Design Flexibility

There’s a persistent belief that modular buildings are cookie-cutter and inflexible. In reality, modular design can be highly customizable. While modules are sized for transportation, architects use clear-span technologies, variable layouts, and hybrid site-built features to deliver creative, flexible structures tailored to your needs.

Myth #2: Modular Buildings Are Only Temporary

Modular buildings can be temporary or permanent. Yes, they serve short-term needs like classrooms or disaster relief—but they can also be designed for long-term use with permanent foundations and custom interiors. Projects like our biotech office expansion prove that modular buildings can be high-performance, lasting solutions.

Myth #3: Modular Buildings Are Lower Quality

Modular construction uses the same materials and codes as traditional construction—including IBC compliance. In fact, factory environments allow for tighter quality control and fewer weather-related delays. It’s a construction method—not a downgrade in quality.

Myth #4: Modular Buildings Are Architecturally Boring

That might have been true decades ago—but not anymore. From sleek childcare centers like our David H. Koch Childcare Center to unique hospitality spaces like the Whistler Athletes’ Village, modular buildings today are modern, functional, and beautiful.

Myth #5: Modular Construction Is Unproven

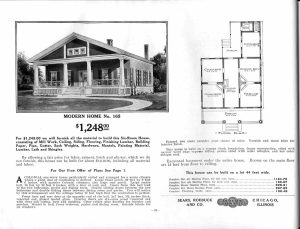

Modular construction has been around for over a century—think of the Sears kit homes from the early 1900s. Today’s modular buildings are even more advanced, and many in use today were installed over 20 years ago. Browse our permanent modular project gallery to see real-world examples still standing strong.

Learn More About Modular Construction

Still unsure about modular? With over 40 years of experience, Triumph Modular has helped clients across education, biotech, government, and commercial sectors realize the benefits of modular construction. From speed to sustainability, we’re here to guide you through every step.

Let’s talk about how modular can meet your needs—without compromise.